A zeolite is a naturally occurring insoluble mineral of the sodium aluminosilicate

type. When hard water passes through a bed of small particles of such a mineral,

an ion exchange reaction takes place (Scheme 8.10). As more and more alkaline

earth metal ions are retained by the zeolite, its exchange capacity gradually

decreases. Regeneration of the sodium salt of the zeolite involves passing a

concentrated solution of NaCl through the zeolite. The calcium and magnesium

ions are displaced and leave with the solution (the reverse of Scheme 8.10). After

rinsing with water to eliminate the excess salt, the zeolite is ready for another cycle

of softening.

Many zeolites occur in nature but they can also be manufactured. The removal

of the alkaline earth metal ions is more effective the greater the surface area of the zeolite particles in contact with the water. For this reason, softening involves

percolation of the water down a packed column of the finely ground zeolite,

followed by periodic regeneration. Although the calcium and magnesium ions in

the water are replaced by sodium ions, these are relatively harmless in textile

processing.The chemical structures of aluminosilicates are based on the structure of silica.This consists of a three dimensional network of SiO4 units, in which the oxygen atoms have a tetrahedral arrangement around the central silicon atom. These

tetrahedra may have common corners or faces. In an aluminosilicate, a number of

aluminium atoms replace silicon atoms in the silica structure. The aluminium

atoms are bonded to four tetrahedral oxygen atoms but because their atomic

number is one less than silicon, each aluminium atom introduced has a negative

charge, balanced by incorporation of a cation such as Na+ or K+. It is these

cations that are available for exchange.

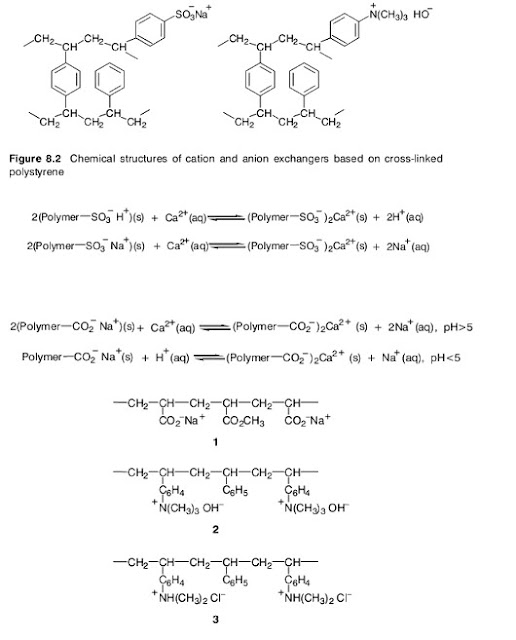

The newer synthetic polymer ion exchangers are much more versatile than the

zeolites and are widely used for water softening and demineralisation. They are

often called ion exchange resins. Many are based on polystyrene that has been

partly crosslinked by incorporation of a small amount of divinylbenzene (2 – 10%).

Suspension polymerisation of the styrene and divinylbenzene produces the

crosslinked polymer in the form of small beads. These have the appearance of a

fine white sand. Sulphonation of some of the benzene rings, mainly on the bead

surfaces, provides anionic sites suitable for cation exchange (Figure 8.2). Since a

sulphonic acid is comparable in strength to a mineral acid, these are called strong

acid exchangers. They may absorb cations and release hydrogen ions, or, in the

form of their sodium salts, exchange sodium ions for other cations in the water

Weak acid cation exchanger, containing acrylic acid (ethenoic acid) units ( 1 );

strong basic anion exchange resin, containing quaternary ammonium hydroxide groups

(2 );weakly basic anion exchange resin with protonated secondary amino groups (3 )

The so-called weak acid cation exchangers are usually polymers containing

carboxylic acid groups, such as vinyl polymers containing acrylic acid (ethenoic

acid) units (1, in Figure 8.3). These are used in the form of their sodium salts.

They do not exchange hydrogen ions for cations below pH 5 since the free

carboxylic acid groups are barely dissociated at low pH values (Scheme 8.12).

Other types of ion exchange resins are available for anion exchange. These may

be of the strong basic type, containing quaternary ammonium hydroxide groups

(see Figure 8.2, and 2 in Figure 8.3), or weakly basic with protonated secondary

amino groups (3 , in Figure 8.3). Either type will have associated counter anions

that exchange with anions in the solution in contact with the resin. The weakly

basic types have ammonium ion groups that can lose a proton in contact with an

alkaline solution and therefore are ineffective above pH 10 (Scheme 8.13). The

ion exchange processes are again reversible so resin regeneration simply involves

treatment with a concentrated solution of a salt containing the appropriate anion.

Therefore, a strongly basic quaternary ammonium ion resin is regenerated using

NaOH solution, and a secondary amine type with NaCl or HCl solution.

The two most important properties of an ion exchanger are its capacity and its

selectivity. The capacity is the number of ions that a given mass of resin is capable

of binding by exchange, normally expressed in milliequivalents per gram of dry or

of wet resin. For example, 1.0 mmol of Na+ is the same as 1.0 mequiv, but 1.0 mmol of Ca2+ is 2.0 mequiv. Therefore, a resin with a capacity of 15.0 mequiv g– 1 would be capable of binding 15.0 mmol g– 1 Na+ or 7.5 mmol g–1 Ca2+. The selectivity of the resin determines how strongly it binds a given ion and therefore its ease of exchange. Clearly, for water softening a cation exchange resin should have a higher selectivity for Ca2+ and Mg2+ than for H+ or Na+. Fortunately, the selectivity is often greater for ions of higher ionic charge.

Besides these two properties, the degree of swelling of the resin in contact with

the water must be limited. The higher the degree of crosslinking, for example from

incorporation of more divinylbenzene in the polystyrene, the lower the extent of

swelling. It is also important that the resin particles have a large surface area and

that water is able to penetrate into the surface pores.

Water can be totally demineralised by firstly exchanging all cations using a

strongly acid form of a cation exchanger. Thus, a solution of salts M+X– becomes a

solution of acid H+X–, the M+ ions being retained by the resin. Subsequent

percolation through a packing of a strongly basic form of an anion exchanger

absorbs the X– ions and liberates HO– ions into the water. These then neutralise the H+ ions from the first step. The result is retention of all anions and cations

and the neutralisation of H+ and HO– to form water (Scheme 8.14). Thus, the

water has been demineralised. It may, however, still contain organic material and

dissolved carbon dioxide from the reaction of carbonate and bicarbonate with the

acid from the resin. A thorough aeration eliminates the carbon dioxide.

Demineralisation is important for water fed to very high pressure boilers.

The use of ion exchange resins for water treatment is relatively simple. The

resin is packed into a column containing water and treatment simply involves

flowing water up or down the column. The capacity of the resin and the ionic

content of the water determine when regeneration will be required. One problem

with beds of ion exchangers is the retention in the column of suspended matter

and living organisms in the water. Countercurrent rinsing and occasional

treatment with a bactericide minimise these problems. For removal of both cations

and anions (demineralisation), two columns in series are used, the first for strong

acid exchange and the second for strong base exchange. It is even possible to mix

anion and cation exchangers in the same bed. If the different types of particles

have different densities, they can be separated by sedimentation in a counterflow

of water, regenerated separately, and then re-mixed. Figure 8.4 shows a typical

series of processes for water softening.

we are manufacture, exporter and suppliers of ion exchange in india since 1954 with a range of mass transfer equipment.

ReplyDeleteThankfulness to my dad who informed me relating to this blog, this website is really amazing. Softeningwater

ReplyDeleteThis is great advice! Very honest and practical.I really enjoyed this post.

ReplyDeletedifference between zeolite and ion exchange process